Description

|

Product Information |

|

|

Product name |

Electronic flow switch |

|

Model |

RFS-D-010L |

|

Response time |

1~13S, typical value 2S |

|

Setting Range |

1-150cm/s (water), 3-300cm/s (oil), 20-2000cm/s (air) |

|

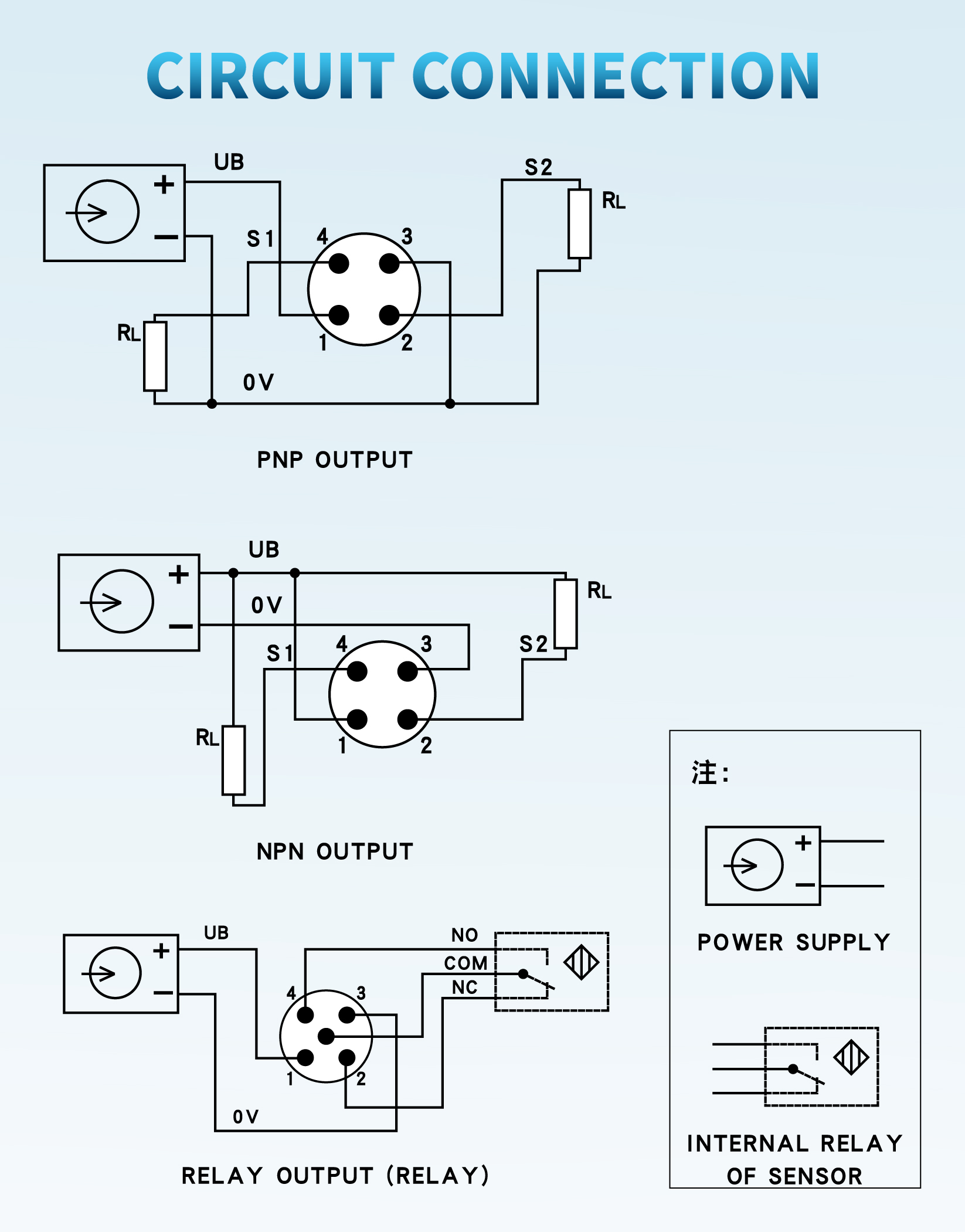

Output |

PNP,NPN, Relay normally open+normally closed (SPDT) |

|

Switched on |

400mA (PNP or NPN type)/zui large 1A@48V(Relay type) |

|

Connection |

M12 connector/optional 2-meter direct attachment |

|

Texture of material |

Probe: Stainless steel shell: Stainless steel PBT |

|

Power supply |

24V±20%DC |

|

Initialization time |

About 8S |

|

No-load current |

Maximum 80mA |

|

Electrical protection |

Reverse, short circuit, overload protection |

|

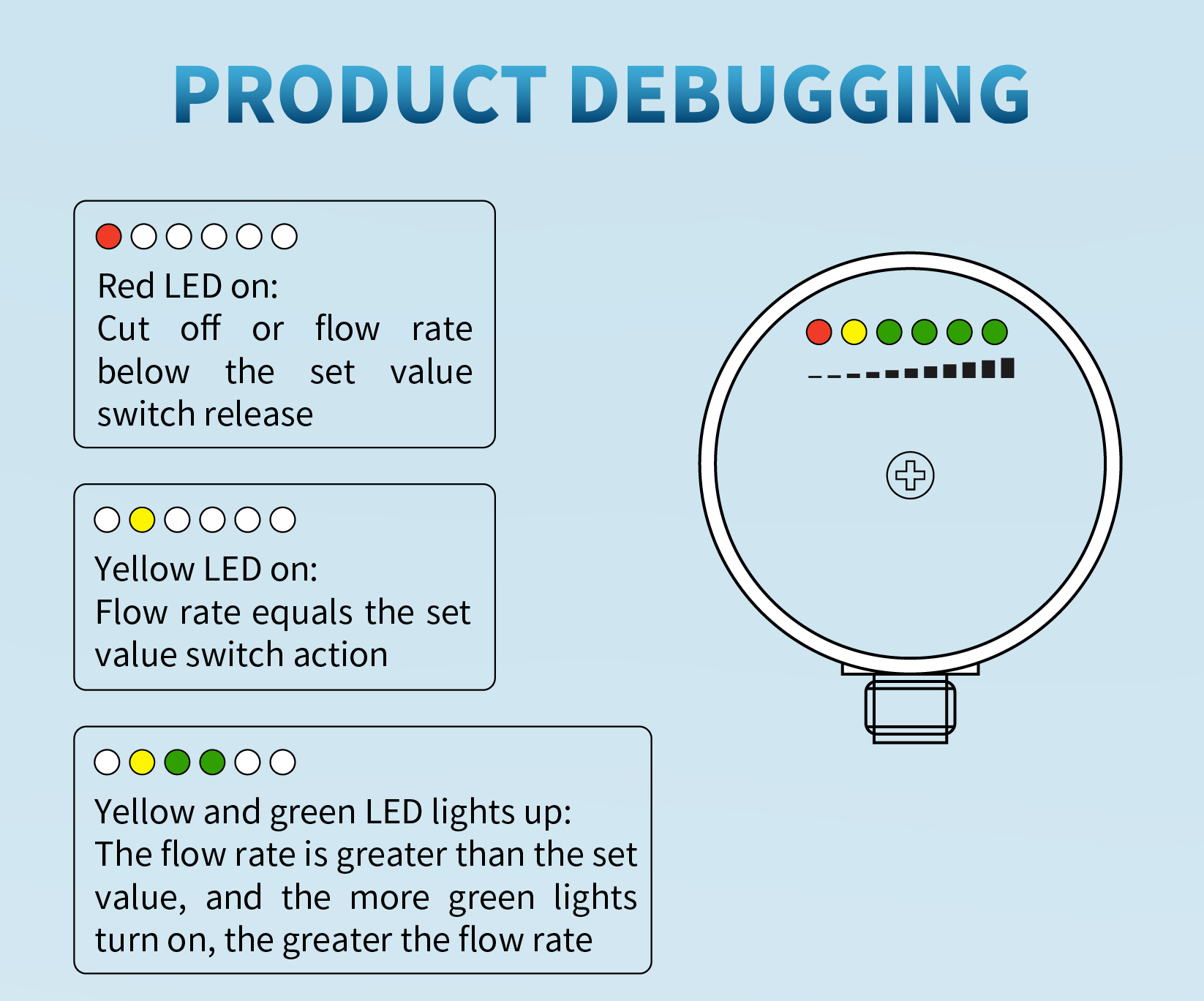

Traffic indication |

LED row (6 pieces) |

|

Protection grade |

IP67 |

|

Setting method |

Potentiometer setting |

|

Medium temperature |

-20~100℃ |

|

Voltage endurance range |

100bar |

|

Ambient temperature |

-20~80℃ |

|

Product size |

53x108x53mm |

|

Weight |

0.4kg |

|

Product weight |

Approximately 2.4kg |

|

Product packaging size |

140x100x100mm(The packaging material is cardboard box) |

|

Repeatability |

± 2% measurement value |

|

Thread |

Default G1/2 (customizable) |

|

Pole length |

Default 50mm (customizable) |

|

Product Display |

||

|

01 |

02 |

03 |

|

Compact probe |

IP67 dustproof and waterproof |

High temperature /high pressure resistance |

|

Plug in installation is convenient Small probe can reduce water resistance Small traffic loss Strong anti pollution ability |

LCD Chinese display Humanized data display The reading is intuitive and clear |

Using standard stainless steel flange connection Good sealing and corrosion resistance |

|

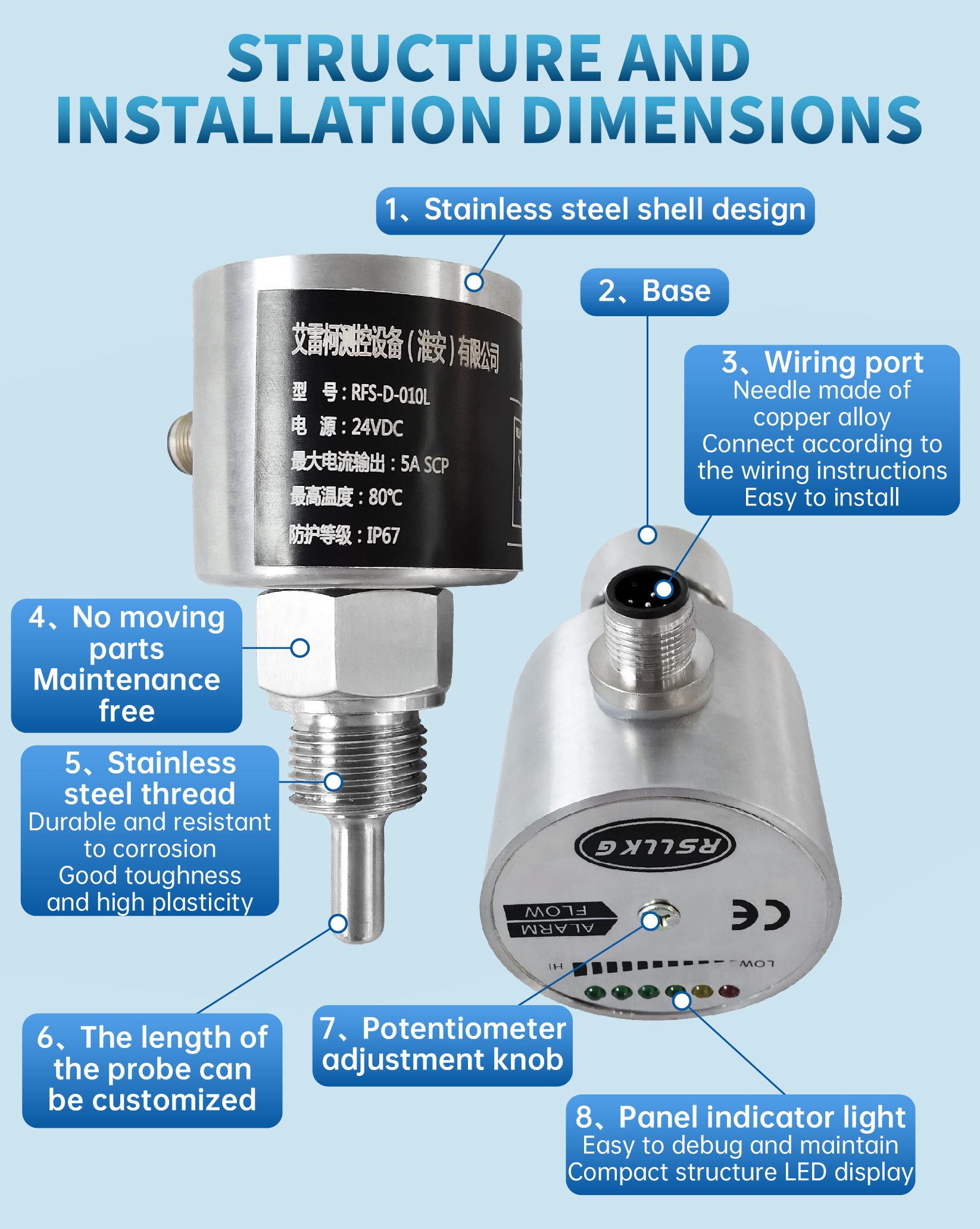

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

|

Stainless steel shell design |

Base |

Wiring port Needle made of copper alloy Connect according to the wiring instructions Easy to install |

No moving parts Maintenance free |

Stainless steel thread Durable and resistant to corrosion Good toughness and high plasticity |

The length of the probe can be customized |

Potentiometer adjustment knob |

Panel indicator light Easy to debug and maintain Compact structure LED display |

Flow setting and adjustment:

After installing the flow switch and turning it on, first enter the initialization process (6 LED lights light up together, after 8S, other lights turn off in sequence, and the red light lights up). After the initialization process is completed, open the pipeline medium to flow. At this time, adjust the potentiometer adjustment knob to monitor the flow rate flow, so that the yellow light turns on exactly. Afterwards, when the flow rate is lower than the current value, the switch is released. To make the switch point smaller than the current flow rate, adjust the potentiometer to make the green LED light up more. Reduce clockwise and increase counterclockwise.

Matters needing attention

1. Regularly check for any abnormalities in the sensor's ding end.

2. Clean the dirt on top with a soft cloth, and for some stubborn dirt (such as lime), vinegar can be used for cleaning.