Description

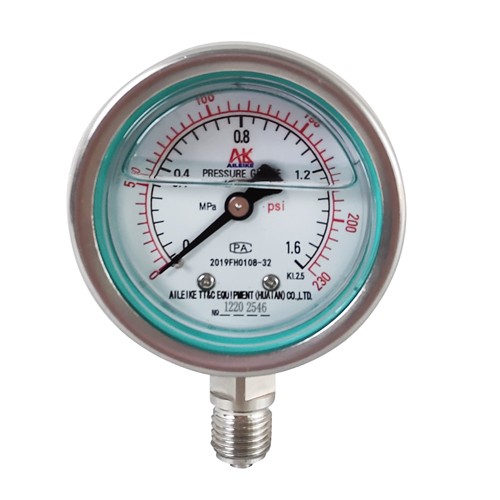

The parts of stainless steel shock resistant pressure gauge y-60bfz are made of corrosion-resistant stainless steel and corrosion-resistant alloy materials, which make stainless steel pressure gauge have good corrosion resistance and are used in petroleum, chemical, mining, machinery, electric power and food industries. Direct measurement of non crystalline, corrosive gas, liquid pressure

The stainless steel pressure gauge is composed of pressure guiding system (including joint, spring tube, current limiting screw, etc.), gear transmission mechanism, number indicating device (pointer and dial) and shell (including case, cover, glass, etc.). The shell is airtight structure, which can effectively protect the internal parts from environmental impact and pollution invasion. For the instrument filled with liquid (usually silicone oil or glycerin) in the shell, it can resist the severe vibration of working environment and reduce the impact of medium pressure pulsation.

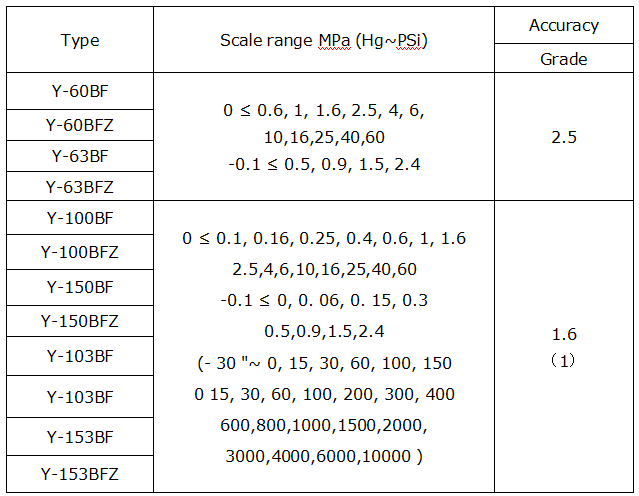

Note: The scale range and precision grade in brackets are for special order only.

Accuracy grade: ±1.6%; Plus or minus 2.5%.

Case diameter: 60mm; 100 mm; 150 mm.

Case material: 304 stainless steel, 316 stainless steel.

Case form: Containment construction, clapboard device after release

Material of elastic element and joint body: 304; Argon arc welding of elastic element to joint body.

Movement material: 304 stainless steel, 316 stainless steel.

Joint thread: M14×1.5; G1/4; M20 x 1.5; 1/2 NPT, etc.

Measuring range: -0.1~0 MPa or,0.1~60 MPa

Ambient temperature:

1) -25~70℃(liquid filled inside the shell)

2) -40~70℃(no liquid filling in the shell)

Temperature influence: not more than 0.4%/10℃(use temperature deviation from 20±5℃)

Anti-vibration of working environment: V·H·4 (liquid filled inside the shell)V·H·3 (liquid not filled inside the shell)