Description

Provide isolated or non isolated RS485 / RS232C digital communication interface, and support modbus, PROFIBUS-DP, Hart and other fieldbus communication modes. Using constant current source to measure the fluid resistance, the internal resistance of electrode signal can be accurately measured in the case of long line transmission. To determine whether the fluid in the sensor is empty or not, it can identify abnormal phenomena such as electrode pollution and coverage, and provide users with fault handling information such as cleaning electrode.

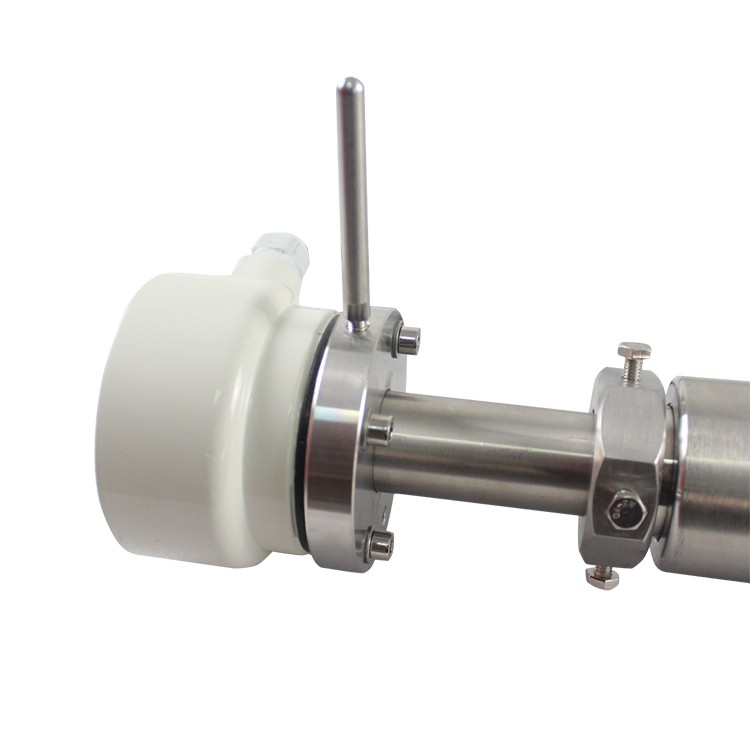

Ldcf-200 electromagnetic flow converter can be used with different types of electromagnetic flow sensors to form a system of electromagnetic flow meter, which is used to measure the volume flow of conductive fluid in closed pipe. It is widely used in petrochemical, iron and steel metallurgy, water supply and drainage, irrigation, water treatment, total amount control of environmental sewage, flow measurement and control of production process in industrial and agricultural departments such as papermaking, medicine, food, etc., and total amount measurement of conductive liquid.

Technical parameters

Precision level:±0.5% R (5/1000)

Nominal pressure:1.6MP (DN10-DN250)

1.0MPA (DN300-DN1000)

0.6MPA (DN1200-DN2000)

(other specifications can be customized)

Installation mode: flange installation(default)

Flange clamping(custom) clamp installation (custom)

Electrode type:316L electrode (default)

HB/HC alloy electrode

Titanium electrode tantalum Electrode; tungsten carbide electrode; platinum electrode lining material: neoprene rubber(CR); polytetrafluorine (F4)

Polyurethane rubber (PU); polyperfluoroethylethene (F46)

Range ratio: 10:1

Working environment: sensors:-25-150 ℃ converter:-10 ≤ 60 ℃

Fluid requirements: conductive media(conductivity ≥ 5US/CM liquid)

Repetitive error

Of the measured value±0.1%.

Type selection

|

Model number |

Description |

|||||||||

|

LDCF- |

□ |

□ |

-□ |

□ |

□ |

□ |

□ |

□ |

-□ |

|

|

Path |

|

|

|

|

|

|

|

|

|

200-2200mm |

|

Lining material

|

J |

|

|

|

|

|

|

|

teflon |

|

|

|

L |

|

|

|

|

|

|

|

Neoprene rubber |

|

|

|

Z |

|

|

|

|

|

|

|

Special order |

|

|

Electrode materia |

M |

|

|

|

|

|

|

316L |

||

|

|

H |

|

|

|

|

|

|

HC |

||

|

|

T |

|

|

|

|

|

|

Ta |

||

|

|

V |

|

|

|

|

|

|

Ti |

||

|

|

P |

|

|

|

|

|

|

Pt |

||

|

Nominal pressure

|

40 |

|

|

|

|

|

Nominal diameter:10~50,4.OMPa |

|||

|

|

16 |

|

|

|

|

|

Nominal diameter: 65~125,1.6MPa |

|||

|

|

10 |

|

|

|

|

|

Nominal diameter: 150~1000,1.0MPa |

|||

|

|

6 |

|

|

|

|

|

Nominal diameter:1200, 0.6MPa |

|||

|

Grounding ring material |

M |

|

|

|

|

316L |

||||

|

|

H |

|

|

|

|

Hc |

||||

|

|

T |

|

|

|

|

Ta |

||||

|

|

V |

|

|

|

|

Ti |

||||

|

|

P |

|

|

|

|

Pt |

||||

|

Output signal

|

A |

|

|

|

4-20mA |

|||||

|

|

B |

|

|

|

0-10mA |

|||||

|

|

C |

|

|

|

Pulse output |

|||||

|

Flow range |

|

|

|

M3/h |

||||||

|

Display |

|

TBS (display: instantaneous, cumulative) |

||||||||

English

English Portuguese

Portuguese  Indonesian

Indonesian  Russian

Russian  Arabic

Arabic