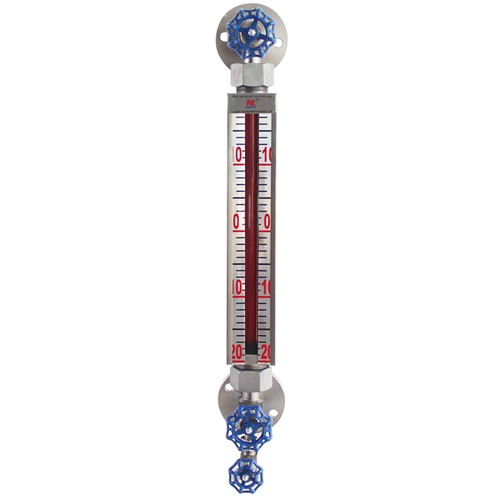

Description

The glass level gauge alkla04 is made of high strength, high temperature and heat resistant glass and high quality materials. It is widely used for liquid level display in high temperature and high pressure medium in petroleum, chemical industry, natural gas engineering and other industrial production

Connection type and size: flange size conforms to hg5012-58, pn1.6, DN20, other flange standards, please note. Thread installation: G3 / 4 "or M27 × 1.5 Joint with steam jacket: external thread G1 / 2 ". Material: carbon steel, stainless steel 1Cr18Ni9Ti Weight: 5-10kg Structure principle of glass tube liquid level gauge: G3 / 4 "or M27 × 1.5 threaded joints are installed on the upper and lower valves of the instrument, which are connected with the container through the flange to form a connector, and the liquid level in the container can be directly displayed through the glass tube. The upper and lower valves of the instrument are equipped with steel balls. When the glass tube breaks due to accident, the steel ball will block the channel under the pressure in the container, so that the container will be automatically sealed, which can prevent the liquid in the container from flowing out. The valve end of the instrument is equipped with a blocking hole screw, which can be used for sampling or discharging the residual liquid in the instrument during maintenance. Outline and installation dimensions: Installation and use of glass tube liquid level gauge Except the valve, the other parts of the instrument are in bulk. The user can install one by one according to the general assembly drawing. See the general assembly drawing. In order to ensure the automatic sealing function, the medium pressure in the container should be greater than 0.2MPa. When opening the upper and lower valves, the number of rotation of the stem should not be less than 4, so that when the steel ball seals the door, it will not touch the top of the stem. Instructions for ordering glass level gauge: Model name Specification (center distance L) Material (ordinary steel or stainless steel) Installation form: G3 / 4 "(M27 × 1.5 or flange installation order should be noted)