Description

Overviews

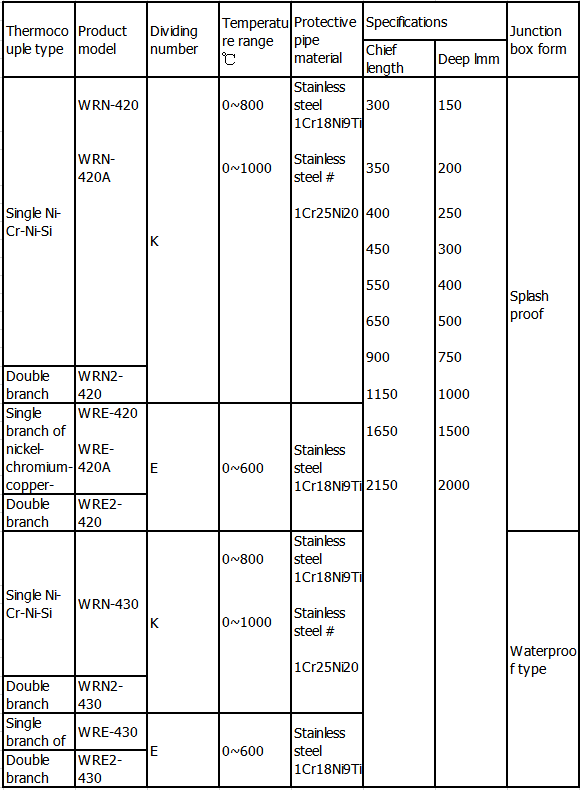

Fixed flange thermocouple WRN-420 industrial assembled thermocouple as a temperature sensor, usually used with display instrument, recording instrument and electronic regulator. It can directly measure the surface temperature of liquid, steam and gas medium in the range of 0 ℃ to 1800 ℃ in various production processes.

Specification

Temperature measurement range and allowable error

|

Thermocouple category

|

Code name

|

Dividing number

|

Measuring range ℃

|

Allowable deviation t ℃

|

|

Platinum and rhodium30-Platinum and Rhodium6

|

WRR

|

B

|

01800

|

±1.5 ℃ or ±0.25%

|

|

Platinum rhodium 10-platinum

|

WRP

|

S

|

0 ≤ 1600

|

±1.5 ℃ or ±0.25%

|

|

Nickel-chromium-nickel-silicon

|

WRN

|

K

|

0 / 1300

|

±2.5 ℃ or ±0.75%

|

|

Nickel chromium copper nickel

|

WRE

|

E

|

0 / 800

|

±2.5 ℃ or ±0.75% |

Model selection:

|

W

|

R

|

Specifications

|

Content

|

||||

|

|

|

R

|

|

Platinum and rhodium30-Platinum and Rhodium6

|

|||

|

P

|

|

Platinum and rhodium10-Platinum

|

|||||

|

N

|

|

Nickel-chromium-nickel-silicon

|

|||||

|

E

|

|

Nickel-chromium-copper-nickel (nickel-chromium-copper)

|

|||||

|

Temperature

|

-

|

1

|

|

Non-fixed installation type

|

|||

|

2

|

|

Fixed thread type

|

|||||

|

3

|

|

Movable flange

|

|||||

|

4

|

|

Fixed flange type

|

|||||

|

5

|

|

Movable flange angle ruler form

|

|||||

|

6

|

|

Fixed thread conical protective tube

|

|||||

|

Install fixed form

|

2

|

|

Splash proof

|

||||

|

3

|

|

Waterproof type

|

|||||

|

4

|

|

Flameproof type

|

|||||

|

Junction box form

|

0

|

Φ 16mm protection tube

|

|||||

|

1

|

Φ 25mm protection pipe (double casing)

|

||||||

|

2

|

Φ 16mm High Aluminium Pipe (single layer casing)

|

||||||

|

3

|

Φ 20mm high aluminum pipe

|

||||||

|

Design serial number

|

|

||||||

FixedFlange thermocouple

Note:1) Thermal response time T0.5 < 90 seconds.

2) the "#" symbol in the protective pipe material indicates that there is no such brand material.

3)nominal pressure: 2.5MPa.

Working principle of thermocouple

Two stages of conductors with different components are welded to form a loop. The direct temperature measuring end is called the measuring end, and the terminal terminal is called the reference terminal. When there is a temperature difference between the measuring end and the reference end, the thermal current will be generated in the loop, which will be connected to the display instrument, and the corresponding temperature value of the thermoelectric force produced by the thermocouple will be indicated on the instrument.